Horizontal milling machines play a vital role in the field of precision engineering, serving as the backbone of many manufacturing operations. These versatile machines offer a wide range of capabilities, allowing for the precise shaping and machining of various materials.

From creating intricate components to producing large-scale parts with accuracy and efficiency, a horizontal milling machine is an indispensable tool in the modern workshop. In this article, we will explore the capabilities of horizontal milling machines and their significance in the realm of precision engineering.

The Evolution and Advancements in Horizontal Milling Technology

The evolution and advancements in horizontal milling technology have revolutionized precision engineering in remarkable ways.

From traditional milling machines to modern computer numerical control (CNC) models, the capabilities of horizontal milling machines have only grown more sophisticated and efficient over time. With enhanced precision, speed, and versatility, todays horizontal milling machines can accurately and rapidly produce intricate components for a wide range of industries.

These advancements have not only improved productivity but also expanded the possibilities for creating complex parts with high accuracy, making horizontal milling machines the backbone of modern precision engineering practices.

Key Features and Components of Horizontal Milling Machines

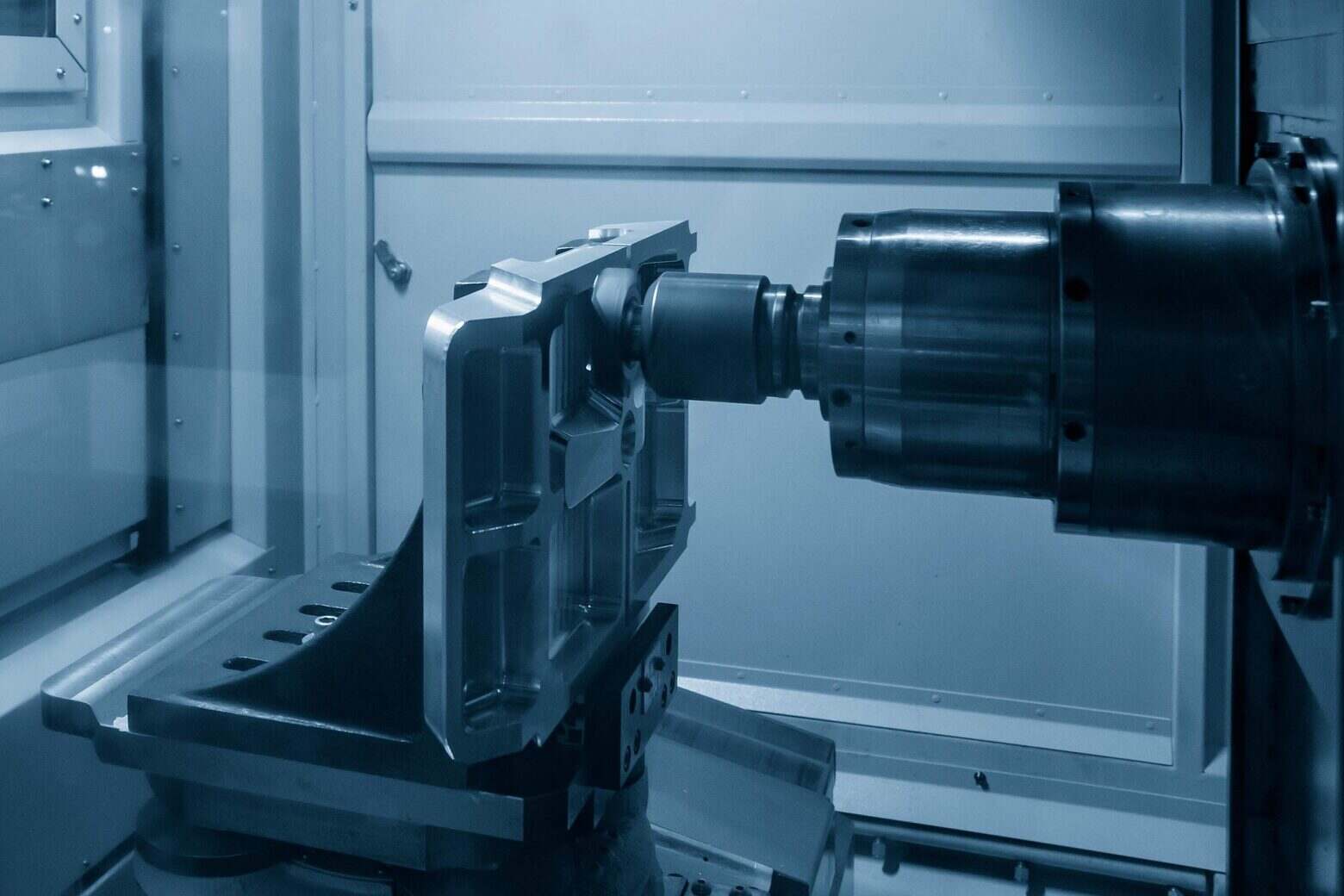

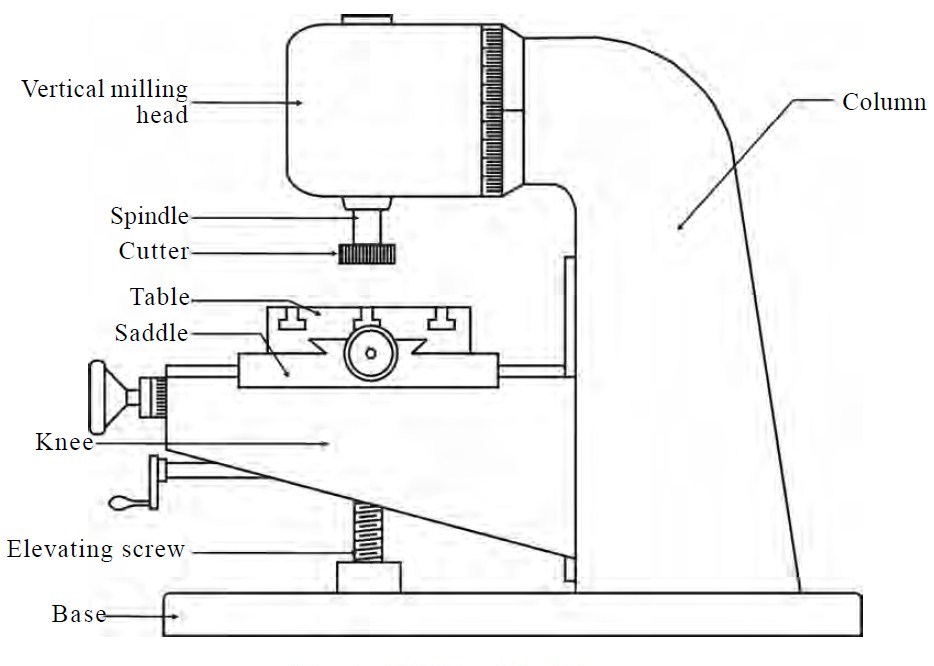

Horizontal milling machines are a key component in precision engineering, offering a wide range of features that make them indispensable in various industries. Some of the key components of horizontal milling machines include the spindle, cutter head, table, and saddle.

The spindle is responsible for holding the cutting tool in place and rotating it at the desired speed for precise cutting. The cutter head, on the other hand, contains the actual cutting tool and can be adjusted for different cutting angles and depths.

The table provides a stable surface for holding the workpiece in place during the cutting process, while the saddle moves the table horizontally to ensure accurate positioning.

These features work together seamlessly to deliver highly precise and efficient machining capabilities that are essential for modern manufacturing processes.

Applications and Industries Utilizing Horizontal Milling Machines

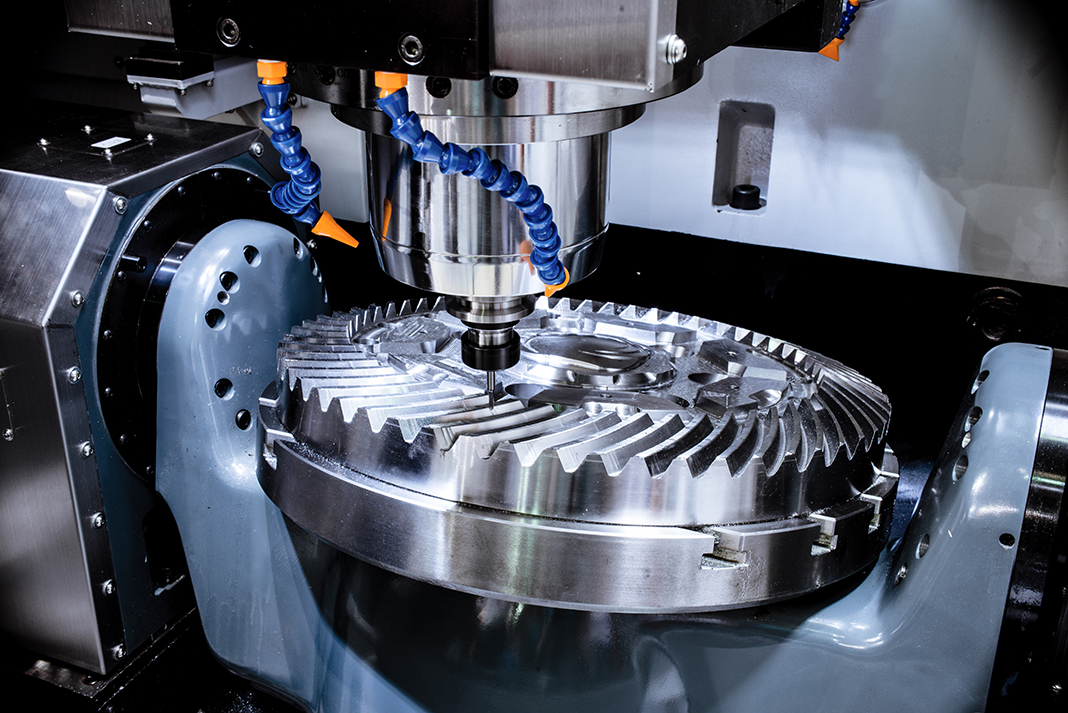

From aerospace and automotive to medical device manufacturing and defense contracting, a wide range of industries rely on horizontal milling machines for their precision engineering needs. These machines are essential for producing intricate parts, components, and assemblies with tight tolerances and high accuracy.

In the aerospace industry, horizontal milling machines are used to machine complex aircraft components such as wing ribs, landing gear assemblies, and engine components.

In the medical device manufacturing sector, these machines are utilized for producing prosthetics, implants, and surgical instruments with precision and consistency.

Additionally, horizontal milling machines play a crucial role in the production of automotive parts such as engine blocks, cylinder heads, and transmission components.

With their versatility, efficiency, and accuracy, horizontal milling machines are indispensable tools for a wide range of applications and industries.

Conclusion

In conclusion, horizontal milling machines play a vital role in the precision engineering industry, offering a wide range of capabilities that allow for the production of complex and intricate parts with high accuracy and efficiency.

With their ability to handle a variety of materials and perform a wide range of operations, horizontal milling machines have become the backbone of many manufacturing processes.

From producing prototypes to mass-producing parts, these machines continue to be indispensable tools for meeting the demands of modern precision engineering.