In recent years, the electronics industry has seen a remarkable transformation due to the rise of online technology. PCB assembly and production is now faster and more efficient than ever before, making it easier for professionals in the field to create new solutions for everyday problems.

From consumer electronics to medical devices, this rapidly evolving landscape is transforming how engineers design their products and introducing unprecedented opportunities for innovation. In this article we will discuss the impact of PCB assembly online technology on the electronics industry and explore how it is changing the way businesses operate today.

Overview of PCB Assembly Online Technology

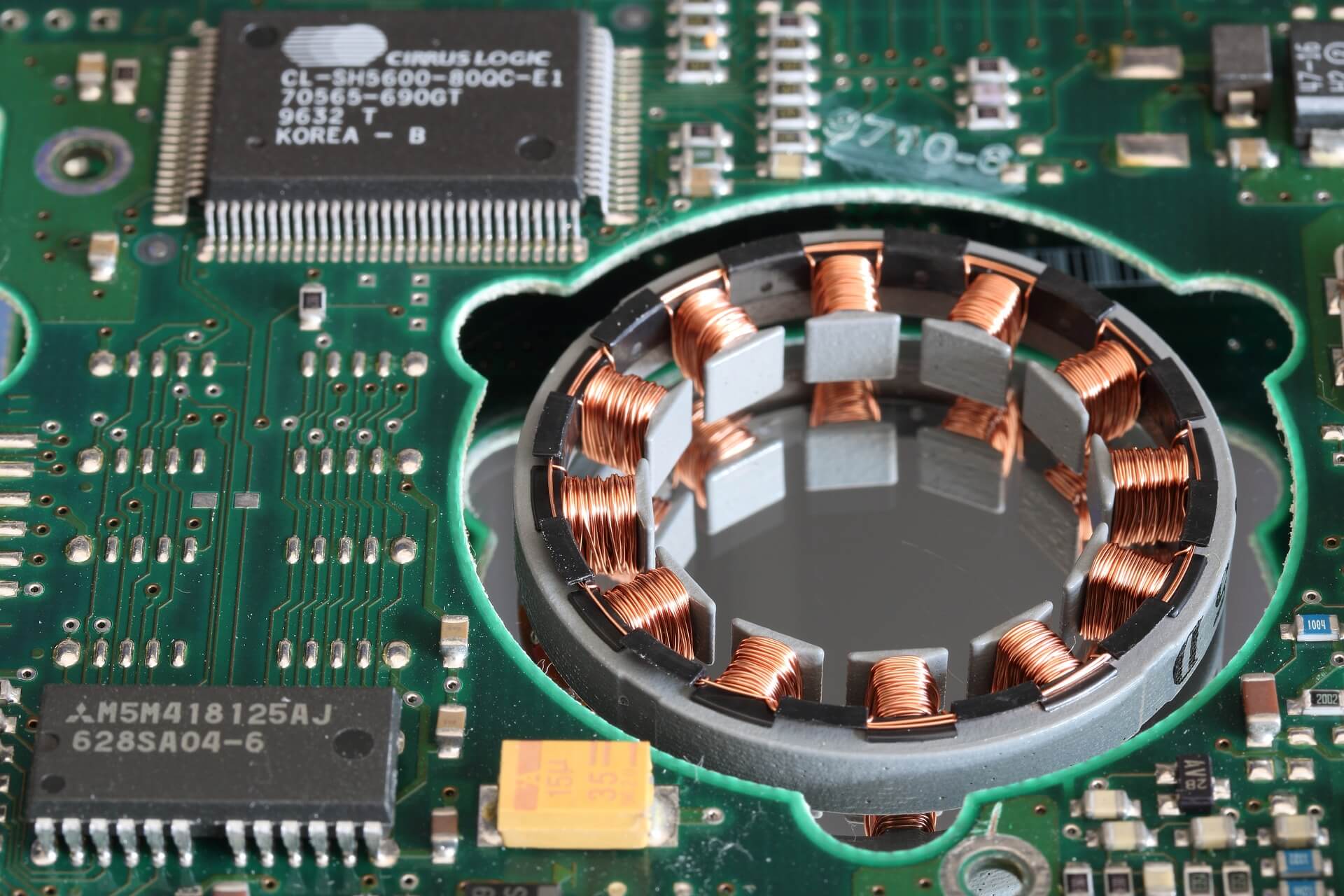

The Overview of PCB Assembly Online Technology section of this article will provide a comprehensive look into the revolutionary impact that this technology has had on the electronics industry. This innovative system allows parts and components to be quickly designed, fabricated and assembled from anywhere in the world with an internet connection. As a result, companies can now produce more complex products faster than ever before without sacrificing quality or cost-efficiency.

The automation capabilities also allow for large scale production runs with increased accuracy and reliability compared to traditional methods. Additionally, the online nature of these systems means that customers have instant access to product information as well as easy tracking of orders throughout their entire life cycle. Furthermore, by utilizing cloud computing resources companies can reduce costs while still maintaining high levels of performance and scalability when needed.

Benefits of Implementing PCB Assembly Online Technology

The implementation of PCB assembly online technology in the electronics industry has provided a range of benefits. Through this technology, companies are able to reduce time-to-market for their products and optimize production processes. Furthermore, it allows them to utilize custom parts from multiple vendors while increasing accuracy in assembly operations.

Additionally, these tools provide cost savings through optimized supply chain management, as well as improved inventory tracking and reduced waste throughout the manufacturing process. As a result, many businesses have been able to improve efficiency and quality control with fewer resources required. Finally, PCB assembly online technology is easy to use due to its automated features that enable users of all technical levels to easily access information and make quick decisions based on real-time data analytics without requiring additional training or expertise.

Challenges and Drawbacks of PCB Assembly Online Technology

The challenges and drawbacks of PCB assembly online technology have had a major impact on the electronics industry. With the proliferation of this technology, it has become difficult to ensure accurate readings and accuracy on circuit boards due to the complexity that comes with manufacturing them remotely. Additionally, calibration processes for testing these circuits can be quite costly when done remotely since each component must be checked individually.

Furthermore, some components may not be compatible with remote assembly due to their size or shape which further increases the costs associated with producing these products. Finally, in order for these services to remain competitive they require a high degree of technical expertise from personnel involved in design and implementation as well as rigorous quality control standards across all stages of production. These issues highlight how important it is for those working in the electronics industry to understand the complexities associated with PCB assembly online technology before investing large sums into its development.

Impact on the Electronics Industry

The introduction of PCB Assembly Online Technology in the electronics industry has had a major impact on both large and small businesses alike. The technology has allowed for faster production times, improved quality control, increased efficiency and more cost-effective solutions. This advanced form of manufacturing has enabled companies to take advantage of new opportunities as well as reduce costs associated with traditional electronic assembly processes.

For manufacturers, this shift in production methods means they can produce high-quality products at much lower costs than before. Furthermore, they are able to develop shorter lead times which results in greater customer satisfaction due to fewer delays in delivery time frames. Additionally, automated features allow for reduced labor costs and improved accuracy when creating complex designs that would be difficult or impossible using manual techniques. On the consumer side, PCB Assembly Online Technology allows an unprecedented level of customization for devices like smartphones and other gadgets by providing better access to product customization options such as colors or design modifications that were previously unavailable due to long lead times or prohibitively expensive production methods.

This provides consumers with greater freedom when it comes to their device design while still ensuring quality components are used since each step is monitored closely during the online process. Overall, PCB Assembly Online Technology has revolutionized how electronic products are designed and manufactured within the industry by allowing companies greater flexibility and cost savings while also providing customers with higher levels of customization options than ever before – ultimately having a huge positive effect on the entire electronics market overall