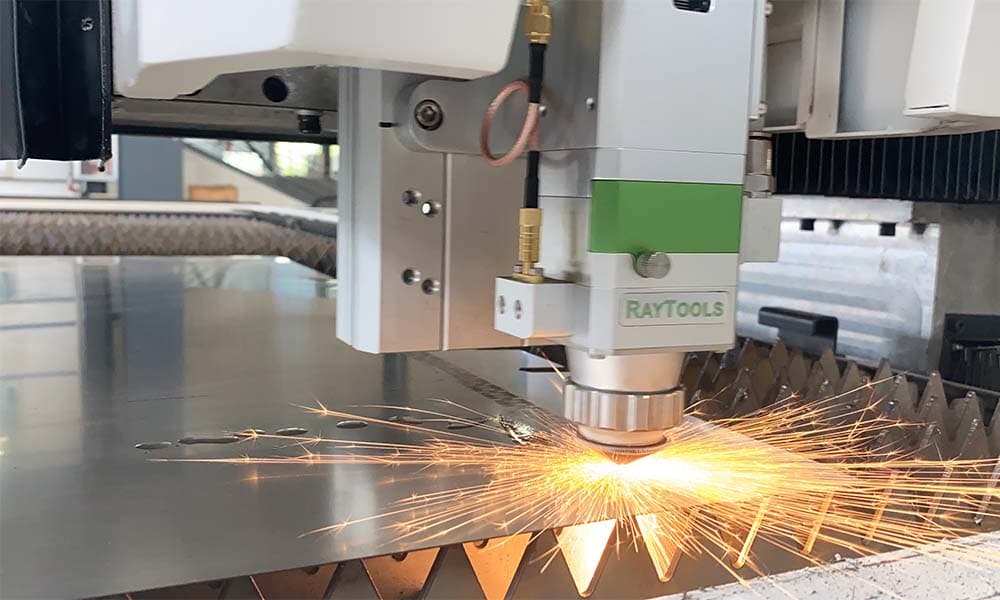

As technology advances, laser cutting machines are becoming an increasingly essential tool in today’s industry. From small businesses to large corporations, the ability to quickly and accurately cut materials is allowing companies to work faster and more efficiently than ever before.

The potential of these tools for shaping the future is immense, as they offer unprecedented precision in material processing that can be used for a variety of applications. With their capability of cutting through almost any type of material with ease, laser-cutting machines are revolutionizing how things are made today.

They have become invaluable productivity boosters for modern manufacturing operations that require high levels of accuracy along with scalability. In addition to their usefulness in industrial settings, laser cutters also provide creative possibilities for craftsmen and hobbyists who want to take their projects up a notch. As the world moves into ever more sophisticated technologies, it is clear that lasers will continue to play an important role in creating new opportunities for innovation and growth across all sectors.

The Benefits of Laser Cutting Machines for Industry

As the demand for precision and accuracy in manufacturing increases, so too needs advanced technology. Laser-cutting machines are among the most important pieces of equipment used in industry today, with their ability to precisely cut through a variety of materials.

This article will explore how laser-cutting machines are being used by industry to shape the future. From automotive production lines to aerospace engineering, laser-cutting machines can be found across industries due to their versatility and reliability. Their high power density gives them an edge over traditional methods such as waterjet or plasma cutting when it comes to precise and intricate cuts that require minimal post-processing cleanup.

Additionally, these machines can easily produce parts with complex geometries including curves and circles which would otherwise be difficult or impossible with other technologies. Furthermore, they have a much smaller environmental footprint compared to some other machining processes due to reduced energy consumption during operation.

The benefits of using laser cutting machines don’t end here – they also offer increased speed when producing large volumes of identical parts while maintaining consistent quality throughout each batch thanks to automated controls that ensure every piece is produced exactly according to specifications without any manual intervention required from operators. Moreover, they generate less waste material than other methods since no additional tools or fixtures are needed during operation making them more cost-effective overall for companies looking for maximum efficiency at minimum expense.

In conclusion, laser cutting machines offer numerous advantages over traditional techniques when it comes to shaping the future of industrial production – from improved accuracy and precision in part production; greater speed; reduced environmental impact; lower costs; and less waste generation – all factors which contribute towards a sustainable business model going forward into tomorrow’s world economy

How Laser Cutting Machines are Shaping the Future of Manufacturing

Laser-cutting machines are sweeping the manufacturing industry, revolutionizing how businesses create and produce products. Today’s laser-cutting technology is more accurate and efficient than ever before, allowing producers to cut intricate patterns with speed and precision.

With these advanced machines, manufacturers can now make products that were previously impossible to achieve with traditional methods. The benefits of using a laser cutter extend beyond aesthetics; it also increases efficiency in production processes while reducing costs associated with labor or materials.

The incorporation of laser-cutting machines has opened up entirely new possibilities for product design and development. By utilizing powerful lasers that generate high temperatures, manufacturers can create complex components that would have been difficult or even impossible to craft by hand or through traditional methods such as milling or machining tools. Companies have taken advantage of these capabilities to reduce lead times on projects while still producing high-quality results with great accuracy levels at reduced costs compared to manual production techniques.

Laser cutting technologies provide an unprecedented level of control over the process of fabrication – from designing intricate shapes quickly and accurately, right down to fine adjustments in minute details during production – so companies can now build parts exactly as they envision them without having any compromises along the way. Additionally, many laser cutters come equipped with software-loaded features such as automated movement settings which allow users greater flexibility in their operations – further increasing productivity whilst reducing operational costs significantly too.

As manufacturers increasingly move towards automation to stay competitive within today’s marketplaces, it is easy to see why investing in a quality laser cutter could be beneficial for businesses looking for faster production speeds accompanied by improved accuracy rates coupled with lower overall costs associated traditionally from labor-intensive processes like handcrafting items manually or relying on traditional machining techniques alone. In conclusion, Laser Cutting Machines are indeed shaping the future of manufacturing — offering unparalleled precision & control at an unbeatable price point!

Exploring the Impact and Potential Uses of Laser Cutting Machines in Todays Industries

Laser-cutting machines are a powerful tool for modern industries. They offer precision and flexibility, allowing businesses to create products with high accuracy and speed.

From automotive production to construction materials, laser cutters are being used in many different sectors today. This article will explore the impact of laser-cutting machines on various industries as well as their potential uses in the future.

The accuracy and speed of laser cutters make them an invaluable asset for manufacturing processes requiring intricate designs or tight tolerances. In addition to increasing production efficiency, these tools can also reduce material waste by precisely measuring cuts on both sides of a piece of metal or other material without having to flip it over for measurement adjustments.

Laser cutters have become especially useful in the aerospace industry where aircraft parts must be produced within strict dimensional requirements set down by engineering standards boards such as ASTM International (formerly known as American Society For Testing Materials). In addition to industrial applications, laser cutting machines are becoming increasingly popular among hobbyists and DIYers who utilize them for creating artworks out of wood, acrylics, or metals – including jewelry-making projects using thin sheets made from precious metals like gold and silver! With digital fabrication technology advancing at a rapid pace, more creative use cases will likely emerge from this sector too; making use of features such as 3D engraving capabilities offered by some models so that artwork can be created with even greater detail than before possible! Overall, laser cutting is transforming how businesses operate through its precision and versatility while providing new opportunities for artists looking to push the boundaries of creativity further into exciting new directions – all thanks to this versatile tool’s ever-growing array of possibilities! As we look towards what lies ahead in terms of our technological advancements when it comes to shaping our future with lasers, one thing is certain: Laser Cutting Machines will continue to play an important role across many diverse industries now -and far into tomorrow!

Conclusion

The use of laser-cutting machines in today’s industry has been a major factor in helping to shape the future. Not only are these machines cost-effective and efficient, but they have also enabled many industries to produce precision products faster than ever before.

The ability to produce complex shapes with precise accuracy and repeatability make them an invaluable tool for industrial manufacturing applications across multiple sectors. With this technology continuing to advance, laser-cutting machines will continue playing an important role in shaping the future of the modern industry.