The modern-day industry is at an all-time high when it comes to the complexity of the machines and devices being manufactured and also when it comes to the volume of devices and machines that are being manufactured. The demand for various machines and devices has never been greater, which means that the competition between manufacturers has never been this fierce.

Every manufacturer, regardless of the industry, is trying to compete and become the best in their field. That means they need superior products, competitive prices, better marketing and so much more. Naturally, to achieve the superior quality of the competition, you must eliminate errors and inspect your products during the manufacturing process, so that there aren’t any faulty ones coming out of your factory, as faulty products would damage your company’s reputation.

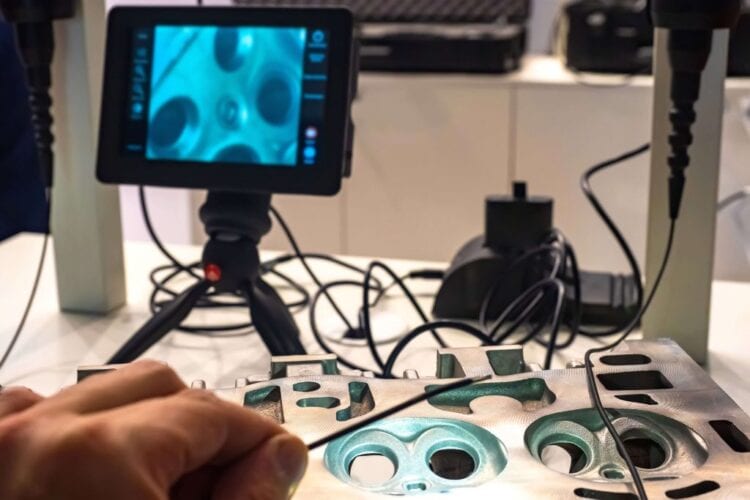

However, inspecting the elements of highly complex devices, machines or vehicles isn’t easy. There are many inaccessible areas that you can’t expect by hand or by eye, so you need to get creative. That’s where videoscopes come in.

What are videoscopes? How do they work? Where are they being used? What are the benefits and advantages of using these instruments? All of these questions must be answered if you want to fully understand what this instrument is. So, without further ado – let’s get started.

What Are Videoscopes?

As we said – videoscopes are instruments that are being used when an inaccessible area needs to be inspected. The process of inspecting those areas is called RVI, meaning remote visual inspection and that’s exactly what these instruments allow us to do – take a good look at something we otherwise couldn’t do.

Videoscopes are a kind of borescopes, only a bit better. They’re the ultimate form of video inspection tools and devices. Basically, they’re a very flexible and durable instrument with a camera and a light source at the end.

How Do They Work?

Videoscopes, as the name says, are equipped with a camera. The camera is located at the end of the insertion probe, which is basically a long, flexible tube that protects the wiring and the optical fibres that are used to transport a digital, visual signal to the body of a videoscope, on which you’d find a screen. If you want to get more into detail on how exactly the science behind this works, feel free to read more about it.

Since these probes are usually inserted into dark, narrow bores, tubes, holes or cavities, the tip of the insertion probe also comes equipped with an LED light source. When you put all of it together, you get a neat inspection tool that is being used in many different industries.

Are Videoscopes And Borescopes The Same Thing?

Even though they serve the same purpose – they’re not the same thing. Videoscopes belong to the ‘family’ of borescopes, only they’re much better at what they do. They’re the most advanced version of a borescope. You could look at it this way – all videoscopes are borescopes, but not the other way around.

Application Of Videoscopes

These tools come in various sizes depending on where they’re being used. You can find videoscopes that are less than 2mm in diameter with 1-meter long insertion probes, but also, you can find the ones with a larger diameter and much longer insertion probes. So, depending on the industry and application – you’d have to choose an appropriate one for your needs.

As far as applications go, there are plenty. You can use them for medical procedures, inspecting equipment condition, monitoring manufacturing processes of certain elements and devices, quality control, video surveillance in special conditions, examination of potential explosive devices and so much more.

Which Industries Benefit From Videoscopes The Most?

When it comes to industries that benefit the most from these devices, we have to mention the aviation and medical industry first. However, that’s not all. Industries and applications of these instruments are various. These can be often found in the military, law enforcement, automotive industry, steel casting, consumer electronics and so on.

Now, we’ve said that the aviation and automotive industry come first and that’s because that’s where these devices are used the most. For instance, in aviation, videoscopes are used to inspect gas and steam turbines, wind turbines, gearboxes, rotating equipment and so much more. All of these areas must be in the perfect state in order for an airplane to take off, fly and land safely and none of them can be thoroughly inspected with a naked eye.

Videoscopes In Medicine

When it comes to medicine – it’s the endoscopes that we’re talking about. Endoscopes are specialized videoscopes used to look inside a human body. The most common procedures using these devices are endoscopy and colonoscopy, the GI tract inspections. However, the digestive tract isn’t the only thing that can be inspected and applications of endoscopes in medicine are broad. Laparoscopy, laryngoscopy, rhinoscopy, enteroscopy – all of these procedures and many more like that are only possible because of the endoscopes.

The Advantages Of Videoscopes

It is not by accident that this tool is so popular in various industries and fields. There are plenty of advantages and benefits to these instruments and we can’t even begin talking about them without pointing out that they save lives and not it’s not just endoscopes we’re talking about.

Sure, diagnosing diseases and various other issues with people is much easier because of these tools – that’s undeniable. Many, many lives are saved each year by timely diagnosed issues during one of the procedures we previously mentioned.

However, the wide variety of diameters and sizes allows these instruments to be used in the automotive and aviation industry as well. Without them, we’d have significantly less-safe vehicles, both on and off the ground.

Of course, there are other advantages to these devices as well, such as a wide variety of application, which is an advantage in its own right. Also, most of these devices are very durable and long-lasting, which makes them a good investment for many businesses out there.

What Does The Future Hold For Videoscopes?

These devices are pretty advanced and great as they are, but there is always room for improvement. Nowadays, the area on which most manufacturers are focused on is improving the video quality. The goal is to reach 4K, sometime soon, which would open up more doors for these devices as they could be used in even more intricate situations.

Also, going as long and as thin as possible is something manufacturers are working tirelessly on.

All in all, the future of videoscopes looks really bright and we can’t wait to see what kind of major improvements are going to be made over the years.

As you can see, these instruments are quite powerful and versatile. They’re being used pretty much everywhere and it’s safe to say that without them, many things wouldn’t be possible. Hopefully, we’ve managed to inform you on these instruments as much as you hoped we would.