In the world of laser technology, there are very few outstanding methods of cutting such as CO2 and fiber. But have you ever wondered which is right for you?

If so, then boy are you in for a ride.

Laser cutting technologies find their use in many, many industries across the world. Some of the more common ones include the automotive, manufacturing, and tons of others.

The primary use of this technology is to be implemented into machines that cut metal plates, stainless steel, and various other types.

This is what makes laser cutting so important in our society. If there is an industry that is responsible for so much of our industry, then it would be natural to bring it close to perfection.

And that’s exactly why we pose the question of CO2 vs fiber. Much can be said about the two, and we’ll try and give you the most important bits of information and hopefully try and formulate an answer for you.

If you’re interested in that, then stick around and find out.

Fiber Laser Technology – What Is It?

The first one we’ll talk about is fiber. You see, fiber has been a breakthrough in the industry. It is younger than CO2 but has achieved so much more. A lot of people will instantly advocate for fiber, and there are an equal amount of counter advocates.

But if there is one thing that fiber has managed to do, it’s to breach the status quo in metal fabrication. With this technology, manufacturers can cut any piece of metal however they like. It is undoubtedly an easier and quite frankly, better way of cutting metal.

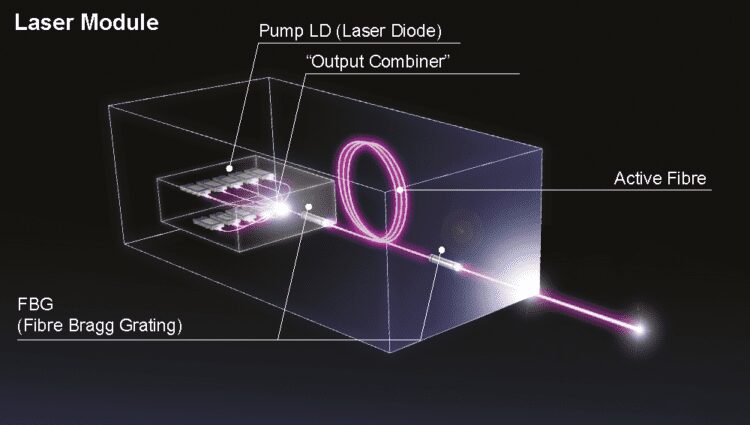

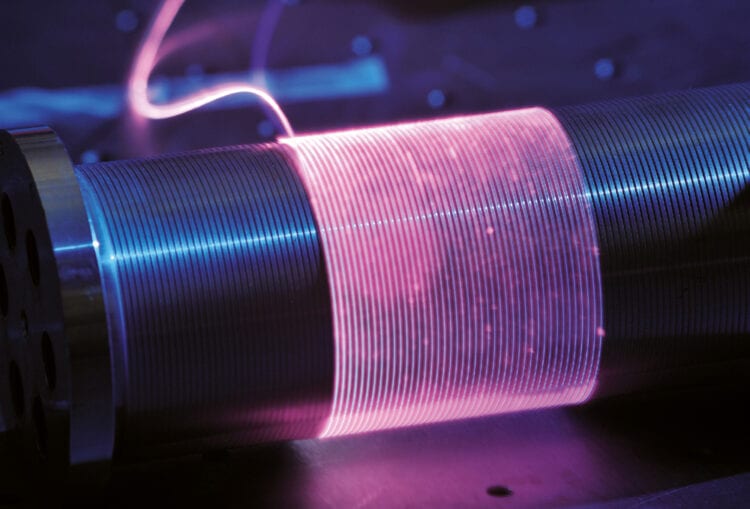

But what makes it better? Well, this technology uses a fiber optic beam as the main component tasked with cutting. And in nearly five years since its inception, this technology has managed to do what CO2 took two decades to do.

By this, we are referring to the 4kW cutting threshold that is effective for cutting most metals. In nearly a decade or so, this tech achieved the 10 and 12 kW threshold range.

For comparisons, CO2 still till this very day hasn’t managed to do it. Fiber is so powerful that some absolute monstrosities exist out there. Some machines are fully capable of breaching the 20kW threshold range and achieve the impossible.

These machines are highly-priced and indispensable for some industries. It’s safe to say that advocating against fiber laser technology is an uphill battle.

Advantages of Fiber Laser Technology

Much can be said about the areas that fiber performs better than CO2. And there are many. For example, the single biggest issue, and the need for a better technology than CO2, was the need for a more cost-effective method of cutting things.

Fiber is definitely a more cost-effective solution!

But that’s not all. There are many other areas as well. Another example is speed. Speed is undoubtedly another area where improvements were needed. So, fiber at a 2kW threshold performs nearly 3 times faster than CO2 at a 4kW range. The speeds between both cannot be compared! The thicker the material, the greater the distance between both technologies.

But not all is doom and gloom. It really depends on what you need. If it’s heavy machinery that needs cutting of thick and large metal sheets, then fiber is the way to go.

Also, this technology offers you better automation and streamlining.

But this tech is much more expensive to buy. So it isn’t really smart to go for it if you’re using it for other, smaller jobs.

That brings us nicely to CO2.

CO2 Laser Cutting – What Is It?

Unlike fiber, CO2 has been around since the 80s. And lots of companies that make these have been in the industry for decades. One such is hispeedlaser.com and you can visit them to see their wide range of fiber and CO2 laser cutting machines.

And it’s safe to say that tons of features don’t exist with fiber but do exist with this technology. One example is the accuracy of these machines. For materials above 5mm in thickness, CO2 machines deliver more accurate results and a smoother surface when finished.

But that does come at the expense of more power and higher cost of operations.

However, there is one area where CO2 is the proclaimed winner. Namely, this technology is perfect when using it for non-metallic materials. This includes the likes of textile, glass, plastic, rubber, wood, and of course, stone.

Each one of these materials performs better when cut with CO2 as opposed to fiber.

Some industries that utilize this tech include the plastic, rubber, and glass industries, among others. These machines are mostly used in the making of PVC pipes, windows, mobile gadgets, electrical components and appliances, and thousands of others.

So, as we mentioned earlier, this tech performs better when needing to cut non-metallic materials and anything that is smaller in size. While the tech is used in mass production, automation is very limited as it is an older technology.

The Verdict

There are many aspects of fiber that are considered better than CO2. Factors such as low operation costs, cost-effectiveness, speed, and power are what separate these two. But the context of what you’re using the machine matters most.

If you need to cut large and thick metal sheets, then you will most likely be on the market for a brand new fiber laser cutting machine.

For those that advocate for CO2, there are clear and obvious benefits to using it. The areas that find most of their use is when needing to cut non-metallic materials.

This means that CO2 performs better across more industries. Both technologies are capable of providing manufacturers with tons of benefits, but context does matter.

Ultimately, you should make the decision based on what works for you. If you’re manufacturing metal components and parts, then go for fiber. If not, then CO2 is a clear and obvious pick.