Whether you need insert molding or overmolding, the characteristics of the job needed to be done dictate the selection. Molding is a process of shaping that has been following us throughout history and has been a vital part of industry ever since the day of its discovery. Using molds enables maintaining set standards and lessens the hard work that otherwise would have to be done if there were no molds to assist. Both insert molding and overmolding cast products are to be seen almost everywhere and living without the benefits of molding would be practically unimaginable.

Also, not every molded item remains flawless, since the quality standards and means of production affect the final product significantly. Whether the product is balanced or not depends on many variant factors. The human factor is definitely one of the main important to notice. Namely, when it comes to molding when a certain part of the assembling process is done by hand, it does not necessarily mean that the product is its best version.

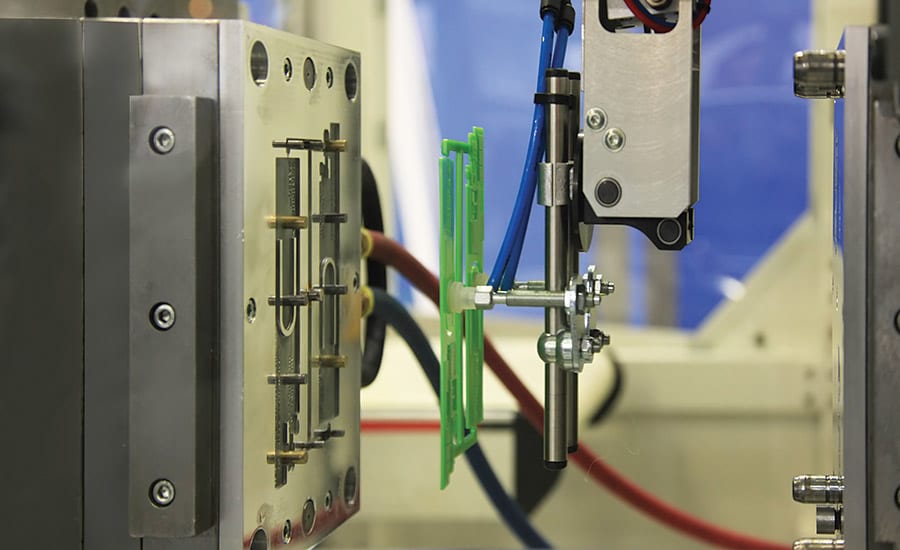

On the other hand, using machines in the molding process proved to be a wise choice concerning both productivity and standardized merchandise.

The automated process enables even time saving because a machine delivers an expected quantity over a certain period, where both quantity and time frame are fixed and expected. What makes automatized molding a preferable way of production is the greater improbability of human error. What differentiates this pair of processes, even more, is the cost of operations. Specifically, molding done by hand proves to be a less expensive way of casting. On the other hand, investing in an automatized production may be a good choice in the long run since it pays itself after a certain period.

We mentioned earlier that utilities crafted by molding help ease of everyday life situations and chores. In the rows below, we will try to explain how different types of molding affect everyday life and what are their main differences as well as their mutual similarities.

The name of the process is injection molding. It implies that the molds, or part of the molds, are injected with a liquid substance to form a desired object inside the mold and to remain firm after the cooldown process is over. The two most popular and top-notch types of molding in today’s industry are insert molding and overmolding. These two techniques often get mistaken one for another since the process of their production is similar yet they slightly differ.

Injection Molding

In order to talk about its partitions, we need to demystify the injection molding. Namely, raw thermoplastic paste enters a large bowl and gets warmed up. It is treated until it melts and then the material is processed to a mold made of firm materials, typically steel. The molds consist of meticulously crafted craters designed specially to correspond to desired product and its measurements. The hot paste fills the craters where it stays until it thickens and reaches its firm form. It needs to be cooled down and after that, it finishes its molding process and is good to go since it has reached its final form for the time being. Therefore it may go further into processing.

Insert Molding

What makes insert molding specific is that it’s consisted of two main parts. It requires one part or segment to be stuck in into another, bigger part. A smaller part is particularly designed and structured to match the bigger molding structure, shaping it as an inside section of the whole. So, the initial part is delivered to the next joining place and there it gets unified with another, larger injection-molded unit. Now the synthetic molding is added and it flows around the initial part to envelop it and conjoin with it in some way. When regarding to materials used, it is important to mention that both parts need to chemically correspond one to another. Professionals often use metal knives having the injected molded synthetic outer parts as an illustration of the insert molding process. You can inform yourself and view more at metalpie.com.

Overmoling

Likewise, insert molding, overmolding represent a type of injection molding. There are many disagreements regarding the distinction between these two processes. One claim they are similar if not the same, while others state there are no factors that make them even.

So, to put things simply. Overmolding is a procedure where parts of different shapes and origins are combined into a single product. Are you familiar with the saying that all cognacs are brandy, but not all the brandy can be considered cognac? Well, the same goes for Injection molding, where overmolding is cognac, and insert molding represents brandy. Either way, when you use overmold as a label you can often simplify the operation, but if you use it too roughly it may cause bewildering.

Overmolding finds its use from medical to military appliances, even your household probably rests on overmolded items. Razorblade holders illustrate it ideally, concerning rubber and plastic parts joined together, one on top of the other. It is a base way of creating multiple tools as well. Screwdrivers, hammers, almost every item having a detached handle has gone through the constructive process of overmolding. Some of the reasons it is implemented are improved grip and agronomical structure, electrical isolation, waterproofing, sound absorption and vibration reduction. Another benefit of using plastics for plastic overmolding is the time required for production. Namely, since it is applied straight on the premade part, it is less time consuming.

So similar, yet so different. Visually you do not see the traces of the working process when looking at the final product made by insert molding. On the other hand, overmolded items make its constituents visible, not lowering the quality but merely highlighting the style of making. Although it is not easy to choose your favorite, the fact that some utilities are made both ways leaves room for the victor to remain undecided. After all they come from the same family so the varieties they offer may prove to be an advantage, much more than a deficit. So, the way you interpret means of production shall make a definite call.