Injection molding has to be one of the more efficient manufacturing processes when producing anything from simple plastic containers, cutlery, plates to more advanced items such as automotive or aircraft parts. This means that both big corporations and small business owners can use this kind of manufacturing process.

As a small business owner, you probably have thought of a brand new product lineup which means you will have to go through all the challenges, decisions and hoops as any other business owner. You will have to decide what kind of materials you will be using and which manufacturing process. These two factors will ultimately decide what level of quality your products will be once they are finished.

Before you decide whether you will want to use injection molding, here are some things you will need to know about it.

What is Injection Molding?

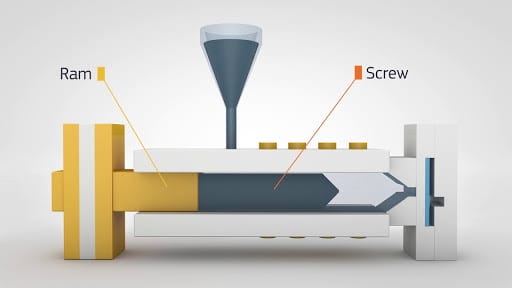

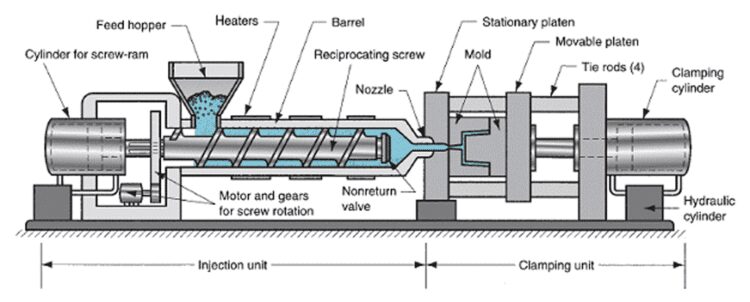

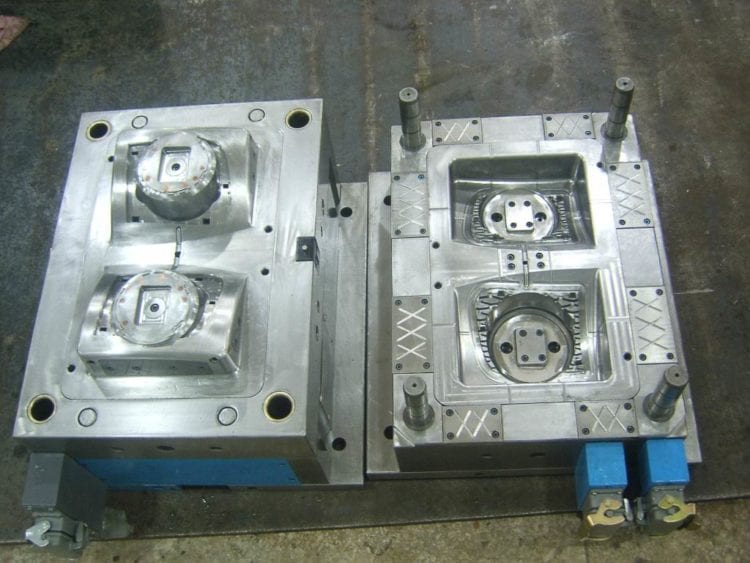

The term itself probably explains that the process consists of injecting a certain material (usually plastic) in a liquid form into a mold. Naturally, the mold is what determines the shape of the final product. There are some companies out there that offer injection of other kinds of materials than just plastic. They can use anything from glass to aluminum and other metals.

Once you have picked the materials you want to use for your product, the workers of the company heat up small granules of it until it turns into molten liquid and then spray it into a mold with a special nozzle that can handle that kind of heat. Once everything cools down, a worker can use the ejector pins of the mold to open it up.

One of the best benefits of using injection molding is the fact that you can reuse the mold created for a certain product thousands of times. In other words, for a small price, you can produce something in high quantities. This is especially beneficial for businesses that have a smaller budget than usual. If you want to experience the benefits of injection molding, you should check out www.qmolding.com.

Advantages

While you are reading this article you are probably getting more and more interested in this manufacturing process which is why we have listed even more of its advantages.

- Low amount of wastes and failures

If you have ever gone through a manufacturing process of any of your products, you are probably well aware of just how much waste there is and how much mistakes are made. Many items come out wrongly shaped, in the wrong dimensions and some other problems that make the product look imperfect. As a business that wants to hold its standard for quality, you want every single item to be perfect. You do not want to disappoint your customers, right?

Well, the great thing about injection molding is that the waste throughout the entire injection process is minimal and the number of mistakes is summed up to a total of just a single-digit number. To put it simply, you won’t have to pay anything extra for a new batch of materials because most of it has gone to waste or because of mistakes.

Everything that doesn’t end up in the mold and falls on the ground can be put into the furnace to be heated up to molten liquid again and then sprayed with the nozzle.

- Consistent and efficient

Another advantage of this type of injection is that it is very consistent and efficient. The process probably won’t change in the next one hundred years which means that the quality of your products will remain consistent throughout the years. You won’t have to worry about companies changing their way of injecting.

If you decide to collaborate with just one company to manufacture your brand new product, the more they produce, the more efficient and accurate they will gate. The same process will be repeated thousands, if not millions of time by the workers which means that the number of mistakes might even be reduced to zero. The quality of the items produce will also rise.

Consistency is what makes customers happy.

- Multiple Items in one go

Many small business owners make the mistake of going with companies that use a different production process and end up with expenses that they cannot deal with it. You might be thinking why? Well, most of these other production process requires multiple mold or different dies to create multiple parts or items at once. So, if your product requires multiple parts to be assembled, the higher the fee of the company you are working with will grow.

Fortunately, with just one injection molds, workers can create multiple parts which mean that no excess materials or extra time will be spent.

- Any color you want

There are absolutely no limitations when it comes to picking the color of the item you want to be manufactured. Any color you can think of on the color palette can be added to your product. Some companies will even give you the option to add complicated finishes or designs.

Alternatives

Naturally, you want to make the best possible decision for your business, so it is smart that you check out alternatives to this type of manufacturing, right? To help you, we are going to mention a few of these other alternatives.

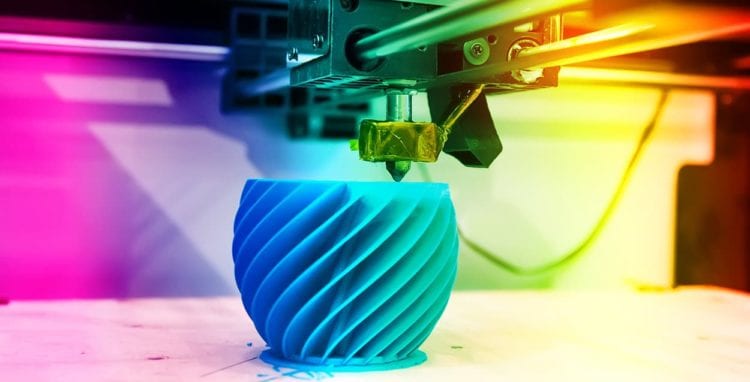

- 3D Printing

3D printing has become quite a popular option these last couple of years. This technology is still quite young, but it is very effective and produces quality products. Many big corporations like to use 3D printing because of how efficient it is and because everything related to it is automated. Naturally, the design has to be made by a human hand on a computer, but after that, everything is done automatically.

- Spin Casting

Instead of injecting and using a steel mold, spin casting uses a rubber one and with the power of the centrifugal force, the parts can be produced. This might be a better option for businesses that like to produce only a small number of parts, otherwise, injection is the way to go.