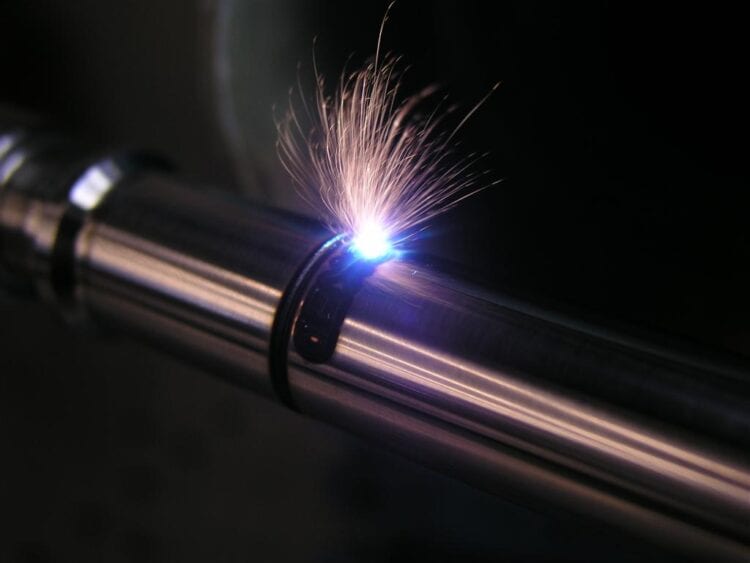

Today, laser marking is an increasingly popular method used when processing various materials. The reason for this is the large number of advantages that this technique compared to all other technologies. By advantages, we mean durability, better quality, and less material used.

When you decide on this method, you have a large selection of markers for marking, because we are talking about different strengths of markers, as well as types intended for different materials and applications. That wide range of offers offered allows you to improve your production systems and performance.

There is no more precise technique than lasers, so it is an ideal choice when it comes to specific marking needs. However, in addition to the many benefits of lasers that generally guarantee that you will always end up with a system designed exactly to suit your project, unwanted complications can sometimes occur. The good thing is that there is a solution for everything, as with any other technology.

It is important to know in advance what potential problems you may encounter when choosing this technology. The most common reasons that lead to this are, for example, poor maintenance due to long use or the selection of lasers whose work is not standardized, etc. For that reason, you have to choose carefully which machine to choose.

Common problems with laser markers:

1. Problem with material marking

This is a problem you may encounter if you are not sufficiently versed in certain ways in which laser marking works. So, this is about the following possibility. You decided to use it, but you did it wrong at the very beginning by incorrectly marking the material. What to do?

Some things you just have to know and prepare for, as well as the consequences of ignorance. However, it is very important that you know the material you are working with. Also, before you get acquainted with it, you must understand its connection with the wavelength, because it depends on which material will be marked.

For example, a certain number of nanometers will be enough to mark wood, on the other hand, you can mark plastic with a significantly higher number. The same thing is with every other material because there is no universal laser that will perfectly suit every material. While some are more accessible, others are more concrete. So pay close attention to the type of material you are marking to avoid this problem.

2. Wrong note you are making

When it comes to a mistake you can make while making laser marking a problem is making the wrong note. What it means? It would look like this … As it should be, you first found out what material you were working with and determine the type of laser that would fit perfectly. However, this is not enough to get the job done well.

You must also be familiar with the technique you choose during the process. Whether you opt for engraving or some other technique will depend on your needs. For example, if you want to remove surface stains, inquire well about the consequences of the technique, because, for example, stain marking leaves a permanent mark on the object. Or if laser-cut metal signs.

If you want to avoid this you have to face the characteristics of each technique before you start working with it. It might be best to check this with experts who can best advise you, evaluate you, and finally guide you to all the other pitfalls of working with it. For example, at dxtech.com you can find which materials the CNC laser cutter is suitable for.

3. Technical problems

Problems like this can be a big problem if they are not detected in time and if you do not know how to recognize them. Properly covered, it will withstand a great deal of adverse conditions. However, you need to know what can happen due to improper machine maintenance. For example, if you have a broken lens, and you have not fixed it as soon as possible, a completely unstable voltage can occur.

Then, water maintenance. Each machine has its own cooling capacity, and you have to pay extra attention to that. However, if it is not something big, and on the other hand you have a large flow of water, you can end up with blocked pipes that bring new problems. This is later transferred to the pumps, so the compressors and you get almost irreparable damage.

When it comes to cooling, you must also take into account the room temperature. The thing is that it is determined in relation to the refrigerator. There should not be too much difference because just such a big difference is responsible for a lot of problem situations. The air humidity becomes too high, and then the lens suffers. So always try to maintain a temperature that is no higher than 3-4 degrees in the room in relation to the refrigerator.

4. Dust

Just as you take care of your house or car, pay the same attention to your machine. Except that it will be easier for you to work with clean objects. You will have a clearer surface in front of you, and the opposite can only lead you to bad situations.

When we say that, we mean frequent mistakes that happen due to poor maintenance. You might never think that this is possible only from dust, but that is exactly why we want to draw your attention to your well-being. The problem arises when the optics, mirror and other parts are very rarely cleaned.

An additional problem is that if you have a larger space where the marker moves, then you get a much greater distance between the mirrors, which means that you have to do more to ensure that they are properly adjusted or flat. The laser is transmitted through them, and it must stand in the correct position so that it does a good job, which means focusing on one point that passes exactly through all the mirrors.

Based on this operation, any stain or dust can lead to a series of bad events, while on the other hand good maintenance leads exclusively to maximum performance and longevity.

Conclusion:

As we mentioned earlier in the text, every technology, including this one, has its pros and cons. However, when the precision cutting of materials in your project is of great importance to you, you cannot go wrong with the choice of laser marking. On the other hand, mistakes are possible, but as you could read-only in case of wrong choices.

To avoid potential problems, it is important to avoid lasers that have unsuitable systems for certain applications. Not every application is intended for the same laser, so the right choice is crucial when talking about potential problems.