If you’re considering starting a CNC machine shop, you’ll want to be familiar with the different types of machines available and the various machining processes that can be achieved with them. In this article, we’ll provide you with everything you need to know about CNC machine shop operations, from equipment overviews to tooling and machining processes. So whether you’re just getting started or you’ve got some experience under your belt, this guide will have everything you need to get started!

What is a CNC Machine Shop?

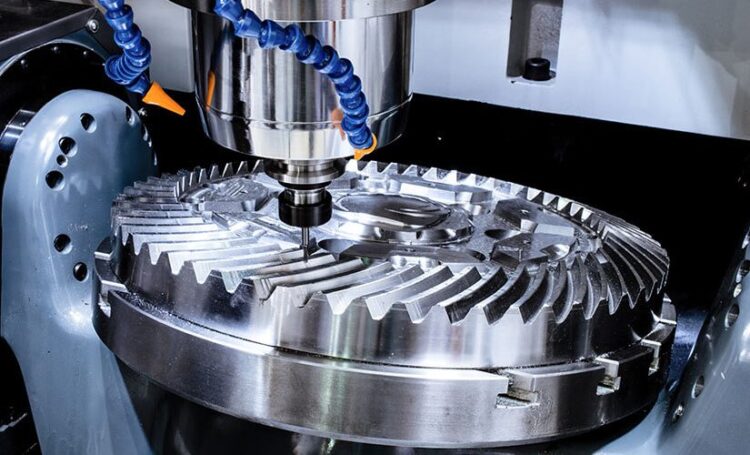

A CNC machine shop is a specialized business that uses computer numerical control (CNC) technology to create high-quality parts and products. A CNC machine can produce parts of almost any shape or size, quickly and accurately, allowing businesses to save time and money on their manufacturing processes.

Types of CNC Machines

There are a few different types of CNC machines available on the market, each with its own strengths and weaknesses. Before you decide which type of machine is right for your project, it’s important to understand the different options.

The three most common types of CNC machines are:

- Direct Drive Machines: Direct drive machines use a set of belts or gears to move the workpiece around the machine. They’re the simplest type of machine to use, but they can be slow and difficult to program.

- Motorized Sliding Mill (MSM): MSM machines use a motorized bed that moves the workpiece across a cutting surface. This type of machine is faster and more accurate than direct drive machines, but they can be more expensive.

- Computer Numerically Controlled (CNC) Machines: CNC machines use computer programs to control the movement of the workpiece. They’re the most accurate type of machine, but they can also be the most expensive.

What Kinds of Materials Can Be Cut With a CNC Machine?

A CNC machine can cut a wide variety of materials, including metals, plastics, and composites. Materials that can be cut using a CNC machine include: copper, aluminum, steel, brass, fiberglass, and fiberglass composites. The types of materials that a CNC machine can cut depend on the machine’s capabilities and the type of cutting tool that is used. Types of cutting tools that can be used with a CNC machine include: carbide blades, tungsten carbide blades, plasma cutting tools, and gouges.

Why Use a CNC Machine Shop?

A CNC machine shop can provide a lot of value to your business. Here are five reasons why you should consider using one:

- Efficiency: A CNC machine shop can efficiently produce high-quality parts faster than any other manufacturing process. Often times, the parts can be produced in significantly less time than it would take to produce them using traditional methods.

- Accuracy: With a CNC machine shop, you can ensure that your parts are very accurate and meeting your specifications. This is especially important when it comes to products that need to meet stringent quality standards, such as medical equipment or aerospace components.

- Customization: A CNC machine shop can also customize parts for you, making it easier for you to get the parts you need quickly and easily. This is especially helpful if you have a large variety of products that need to be customized differently each time they’re produced.

- Speed: A CNC machine shop allows you to produce high-quality parts at a much faster pace than traditional manufacturing processes. This can save you time and money in the long run, since your products will be more efficient and accurate.

- Reduced labor costs: A CNC machine shop can often reduce the amount of labor required to produce a part by using automated machines. This can save you both time and money, since you won’t have to pay employees to produce the parts.

How to Choose the Right CNC Machine for Your Needs?

Machines are a vital piece of equipment in any shop, and choosing the right one can be daunting. With so many different types and prices to choose from, it can be hard to know where to start. In this blog section, we’ll outline everything you need to know about choosing the right CNC machine for your needs, from budget constraints to specific requirements.

If you’re starting from scratch, your first step is determining your budget. While there are certainly machines out there that are more expensive, don’t let that stop you from finding the perfect machine for your needs. There are plenty of mid-priced machines that offer great value for the money. Just be sure to do your research and compare prices before making a purchase.

Another important factor to consider when selecting a CNC machine is the type of work you’ll be doing. If you’re primarily a woodworker, for example, you’ll want to invest in a machine that’s specifically designed for woodworking tasks. But if you plan on using your machine for other types of projects as well, you may want to look into a more versatile machine that can handle multiple tasks.

And finally, don’t forget to consider your specific needs when it comes to CNC machines. Some of the most popular machines are designed for use by hobbyists or small businesses who don’t need all the bells and whistles offered by more expensive machines. If you’re planning on using your machine for commercial or industrial purposes, be sure to research the different types of machines available and decide which one is right for you.

Setting Up a CNC Machine Shop

If you’re thinking about starting a CNC machine shop, you’ll want to start by taking the time to set it up correctly. In this article, we’ll cover everything you need to know about setting up your CNC machine shop.

- First and foremost, you’ll need to make sure that your workspace is well-maintained and safe. You don’t want to risk injuring yourself or damaging your equipment while setting up your shop. Make sure to wear proper safety gear and use caution when moving around the workspace.

- Next, you’ll need to choose the right CNC machine for your needs. There are a variety of options available, so it’s important to find one that fits your specific needs. You’ll also need to decide on the type of material that you will be working with. Some machines are better suited for woodworking, while others are better for metals.

- Once you have decided on the type of machine and the material that you will be using, you’ll need to buy or rent the necessary tools and equipment. You’ll need a computer with a CAD program installed, a CNC controller, laser cutters and other cutting tools, and an appropriate work surface.

- , it’s important to learn how to operate your CNC machine. Once you have the basics down, you can start creating your own designs.